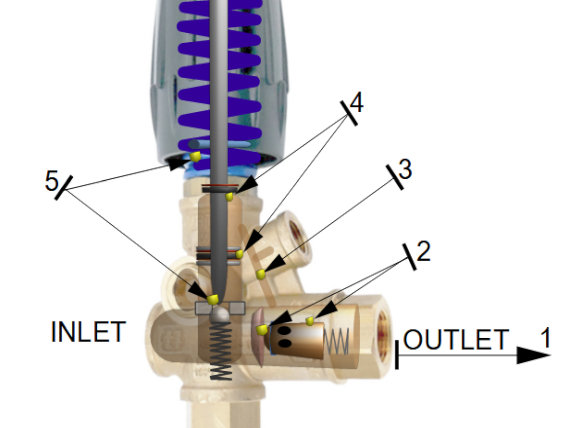

Why newly installed unloader does no work in by-pass mode?

In order to recognize the causes of operational failures, you must first know the principle of operation of UNLOADER - see the adjacent entry: "How does the by-pass unloader work".

In service practice, it often happens that a newly installed unloader does not "reflect" - it does not go into by-pass mode - the complete opening of the bypass, allowing the pressure on the pump to drop. Below are possible causes and ways to remove them. It should be mentioned here that the unloaders are complicated and sensitive - the manufacturers have made them easy to replace, using fitted O-ring seals - for repeated dis- and assembly without additional sealing agents.

Activation of the unloader actuator - complete opening of the discharge valve will not occur if:

1. The high-pressure receiving installation is not tight - it has a constant significant leak:

- end device - most often the gun is not completely closed at high pressure > install the ON-OFF or LPW gun

- completely or partially leaking discharge valve 120-150-200bar - a small 1/4" valve used to reduce the pressure during winter circulation or foam-gun switching in car washes with LPW guns; these valves usually have hoses installed that discharge the "dumps" to the sewage system, leaks are therefore not directly visible > repair, change or temporarily eliminate the dump valve;

- receiving installation leaking - large leakage from the swivel / fitting or damaged high pressure hose - the leak must be significant, but small enough to allow the pressure to be increased > seal, replace the element

2. The check valve does not work - it is leaking and does not allow the pressure to increase in the regulator's output chamber when the flow stops:

- check valve pin obliterated in the chamber by a particle - a foreign body: a small fossil of powder, sediment, rust, a metal fragment - a thread claw, a rubber particle > unscrew the regulator output fitting, which is the working seat for the valve pin - check its position, restore mobility;

- strange element between the flange and the face of the pin with O-ring - the valve does not close > after unscrewing the output fitting and removing the plug - check/clean the flange

3. Control channel blocked - a relatively large strange body - e.g. a piece of rubber has been forced into the channel, effectively blocking it > dismantle the check valve and the pin with the flask and/or a special inspection of the channel - check and unblock the clearance

4. Leaky actuator cylinder - unlikely in a new regulator - only possible in case of faulty assembly or a splinter stuck under the piston or stem O-ring > remove the foreign particle, replace the O-ring;

5. Actuator stem movement blocked:

- a hard particle is blocking the movement of the actuator from the inside between the end of the stem and the release valve < remove the stem with the stock and remove the obstruction

- a small particle in the guide of the pin setting the pin position - covered by the spring, effectively blocks the movement of the pin < unscrew the stock, remove the spring, remove the obstacle

6. Other cases or their co-occurrence are probable.